Spring is the season of new life and new growth, and perhaps this year, a new way of looking at the same old manure. Changing up your manure application can help you avoid the potential yield loses associated with low fertility soils. If your feed crops take the biggest bite out of your budget, you are not alone. For many producers, saving money on feed crops would have significant impacts on their bottom line.

So how exactly is manure the answer to better feed crops?

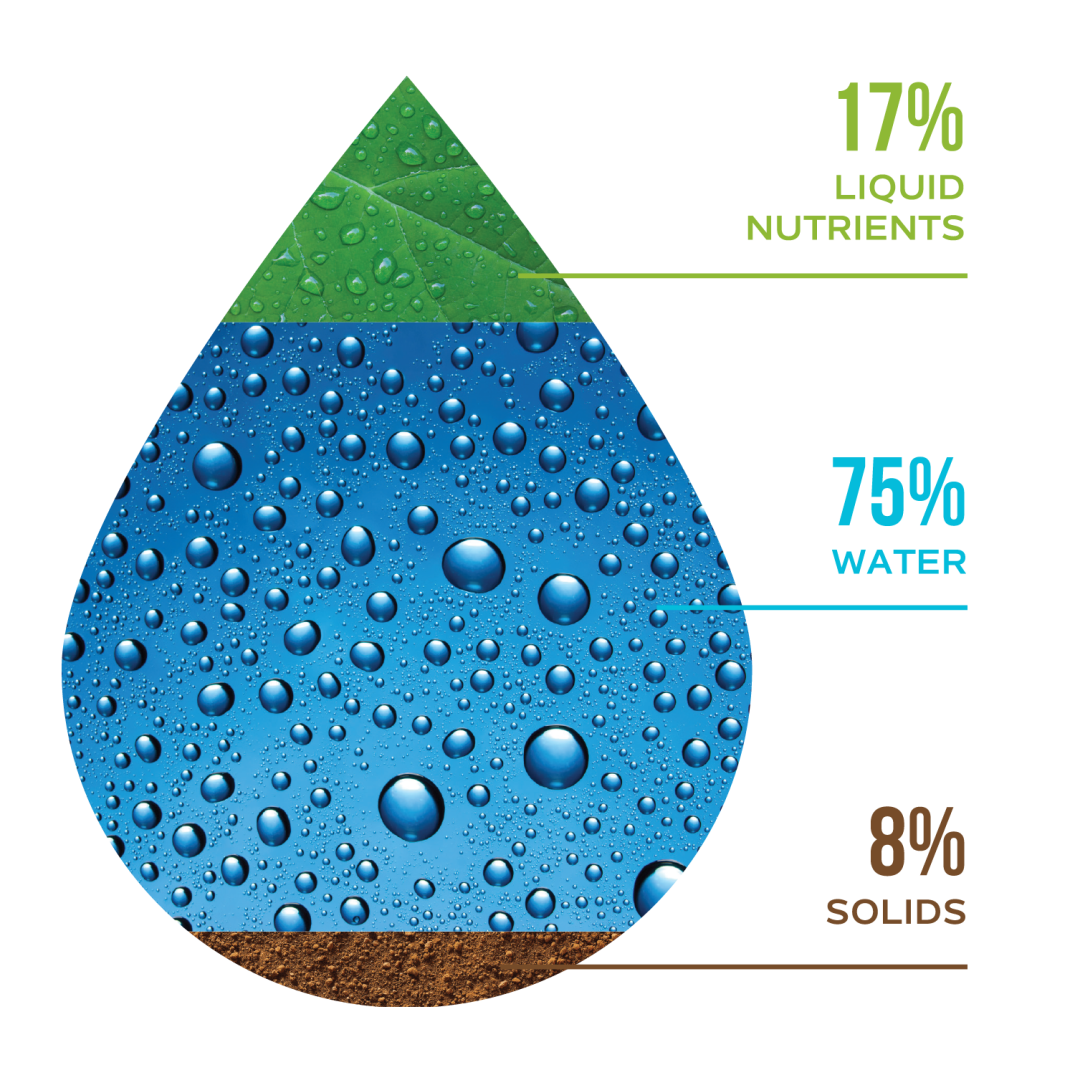

Segregating manure into two separate fertilizers gives you more control over nutrient application. By separating the nitrogen, sulfur, & potassium into a liquid fertilizer while capturing the organic nitrogen and phosphorus in a solid fertilizer, not only will you save money, but you will ultimately end up with balanced soil conditions – and is there anymore more critical to crop production than healthy soils?!

Applying the solids free liquid fertilizer on fields close to the dairy will save you money without reaching nitrogen requirements. Drag lining the liquids close to the barns can cut the cost of hauling manure in half while dropping phosphorus levels in the soil. This practice will also eliminate the need to buy 28% commercial fertilizer!

By reducing the volume of the solid fertilizer, that now consists only of organic nitrogen and phosphorus, this can be hauled away to distant fields that have low phosphorus levels. Not only will this help to regenerate fallow fields, it can also increase corn yields by 3-5 tons per acre.

The LWR nutrient fertilizers were the subject of a growth trial competed by the Olds College Centre for Innovation. The research project evaluated the fertilizer outputs of the LWR System through a series of grow-tests.

The study tested the 2 fertilizer outputs of the LWR System and confirmed that the liquid fertilizer contains adequate amounts of nitrogen and trace minerals suitable for growing plants. The results also confirm that the liquid fertilizer is free of phosphorus, with lab analysis showing phosphorus levels at 0.0000%.

The Old’s study also determined that the nitrogen and potassium in the 50% LWR liquid manure fertilizer is more easily adsorbed by corn than when compared to a commonly used all-purpose plant food. Corn that was fed the all-purpose fertilizer absorbed 7.958% of input nitrogen and 9.105% of input potassium. When given the 50% LWR liquid solution, percentages of absorption increased to 22.87% and 24.98%, respectively.

The phosphorus that is removed from the liquid nutrient is captured in the dry solid fertilizer. In the dry solid growth test, it was found that when mixed at 25% with soil, corn had the highest recorded heights of all treatments when compared to commonly used all-purpose plant food. This indicates that under the correct mixing ratio, the LWR dry solid fertilizer supports the growth of corn.

Half of all agricultural land is currently used for the production of animal feed, and it is estimated that an additional 280 million hectares will be required to meet the future demand of animal production. This means that increasing the productivity of existing feed crops and regenerating fallow fields will have a tremendous effect on the future of food production.

Newtrient, a company founded by 12 leading milk cooperatives representing nearly 20,000 dairy farmers producing approximately half of the nation’s milk supply, knows the true value of manure – especially at this time of year. They know that the proper use of manure reduces the reliance on commercially mined fertilizers that often have to travel great distances. They also know that thoughtful use of manure will result in healthier soils, increased crop yields, and improved economics.

Increasing the productivity of feed crops through precision nutrient application is an imperative piece of this puzzle, and an exciting benefit of manure treatment technology. Remuneration will come in the form of elevated yields and possibly improved crop quality, especially forages. These returns are measurable and can be valued.

Check out Bucky Organics to learn more about the organic plant nutrients made daily by cows in Wisconsin, and the fertilizer benefits of segregated cow manure!